The importance of extractables & leachables screening has grown with increased utilization of one-use systems. Consequently, E&L tests is a regulatory prerequisite to reveal that leachable impurities from plastic products Employed in the processing of a professional medical solution don’t interfere Using the active pharmaceutical ingredient, making sure patient security.

Typically, predefined locations (commonly 10 cm × 10 cm) are swabbed or rinse samples are gathered that has a acknowledged quantity of solvent. The formulation used to estimate the swab or rinse limit for each MACO are as follows:

Makers ought to set up a sampling program to find out the destinations and frequency of sampling over the cleaning approach. The strategy need to take into consideration each Visible inspection and analytical tests to ensure that all residues and contaminants are correctly taken off.

— the utmost period that tools can be remaining dirty before staying cleaned in addition to the institution of the time that should elapse after cleaning and prior to use;

If Now we have indentified that our most stringent is visually clean, can we nevertheless need to validate the analytical method?

Calibration in the instrument was done to ascertain linearity from the method. Linearity was studied by analyzing a sequence of normal options containing 0.

eleven.2 Each and every problem must be assessed independently. read more The method wherein restrictions are founded should be diligently more info regarded. In creating residual limits it might not be sufficient to concentration only to the principal reactant, simply because other chemical variations may be more challenging to remove.

At Pritchard, we provide cleaning & disinfecting services together with the choice to conduct a verification method. Soon after Every single cleaning celebration, the validation ensures equipment fulfills the right criteria in advance of reuse.

The validation review: The ability from the cleaning protocol to proficiently take out contamination from the facility and machines has to be validated. The validation analyze is required to exhibit the cleaning approach and protocol are effective and robust.

Check out visually no stagnant drinking water shall be allowed to continue to be inside the machines subsequent to cleaning Procedure.

An item or list of disorders encompassing the higher and reduce processing limitations for operating parameters and situations with SOP which pose the best possibility of product or process failure compared to best situations. This kind of conditions usually do not always contain merchandise or approach failure.

I want to join newsletters from Sartorius (Sartorius AG and its affiliated organizations) centered of my private passions.

If the actual carryover is over the new acceptance conditions, the cleaning validation study shall be prepared on a few consecutive batches.

The assertion can be justified like worst-case goods with the worst tools chain (having optimum surface area area) are validated properly,

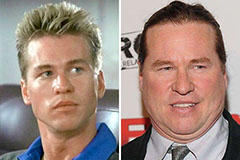

Val Kilmer Then & Now!

Val Kilmer Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!